Who would have imagined that growing mushrooms gave farmers regular nightmares! Wait, you didn’t know? Want to know what makes mushroom farming so tough? Prana Air dug in, found out about the problems related to CO2 monitoring in mushroom farming, and formulated the solution. Read more to find out.

Mushroom Farming: A roller coaster

A lot of us like topping our pizza with mushrooms. But, we remain unaware of the blood and sweat that goes into managing a mushroom farm. Growing mushrooms is not less than a roller-coaster ride. The growth cycle contains two major phases- the vegetative phase and the reproductive phase. The mycelia of mushrooms expand and mature into fruiting bodies in the first phase, and those bodies produce and disperse spores in the second phase. This class of fungi has a tumultuous growth cycle of around thirteen weeks involving fluctuating concentrations of temperature, humidity, and carbon dioxide.

Carbon dioxide is vital to both phases of mushroom growth. However, maintaining the farm requires wavering optimal concentrations of carbon dioxide during different stages. The required concentration of carbon dioxide depends on the type of mushroom. It also depends on the stage of the growth cycle. Different values incubate the fungi in various ways-altering their growth vertically and horizontally. Similarly, optimum temperature and humidity are also specific to the type of mushroom.

CO2 Monitoring in Mushroom Farming- A Challenge

Carbon dioxide (CO2 ) is a metabolic product in mushrooms. It is a primary determinant of their yield and quality. During the initial phases of growth, called the spawn run, the edible fungi require elevated levels of carbon dioxide (10,000-20,000 ppm).

After the growth becomes evident, the optimum requirements change. The farmers need to maintain the CO2 concentration between 800 to 1500 ppm, depending on the nature of the mushroom.

- At a concentration less than 800 ppm, the mushrooms become too small and numerous.

- At levels exceeding 2000 ppm, the quality of mushrooms is deplorable. In this case, the stem height is very long, and the cap is too small.

- A higher concentration of 4000-5000 ppm hinders the development of the mushrooms.

- New mycelium grows at a value beyond 5000 ppm.

Isn’t it daunting? The precise and oscillating optimal values make mushroom farming a very exhausting task. The saddest part is that all the mushrooms that do not meet the quality have to be thrown away. Therefore, the yield would be much less. It implies that the lack of proper CO2 monitoring in mushroom farming would result in all the hard work and investment going in the drain.

How Prana Air turns the challenge into an opportunity!

Mushroom farms require a smart CO2 control system to ensure smooth growth and desired yield.

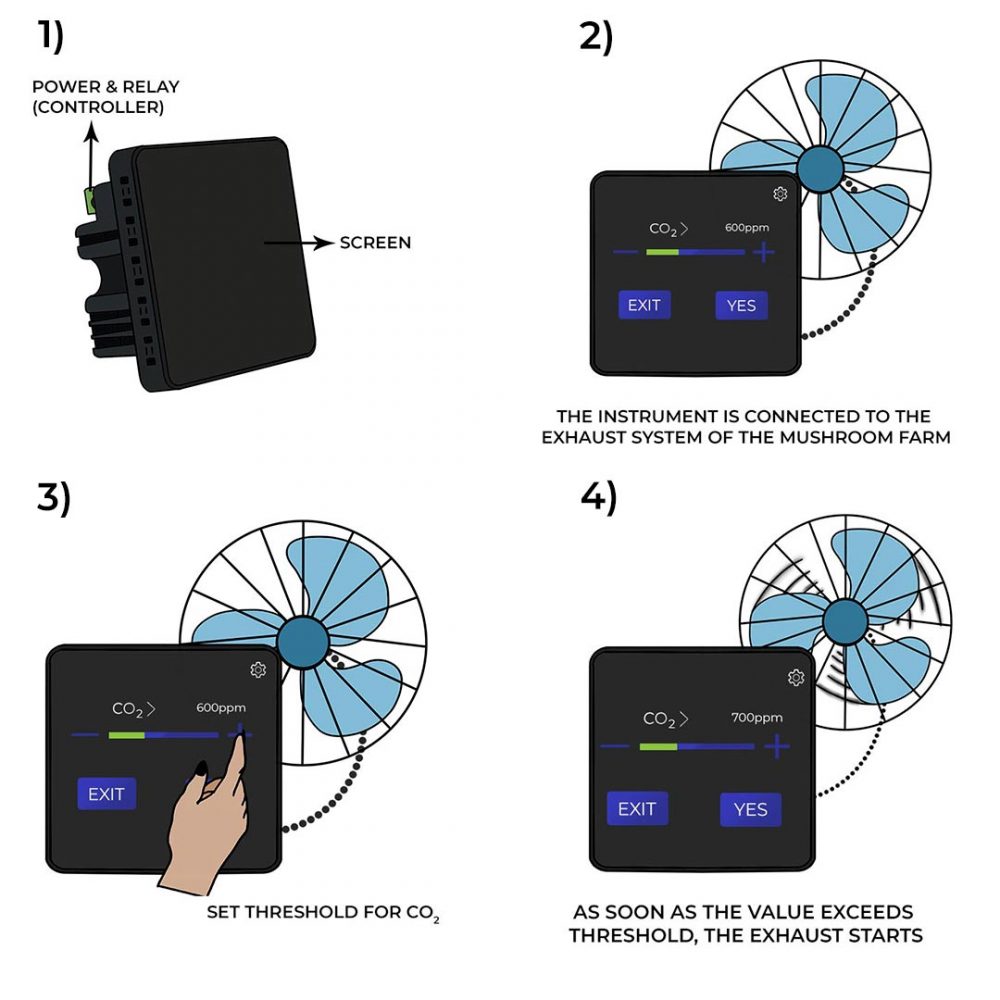

If you are planning to start mushroom farming or already own one, then Prana Air has the solution to the nightmare of your life. Our CO2 monitor has relays, which will resolve the hassle of manual regulation of CO2 levels. All you have to do is connect the instrument with the exhaust system of your farm, and set a threshold for carbon dioxide. As soon as the value exceeds the limit, the relay will activate the exhaust system to balance the concentration. The exhaust will automatically switch off as the value retreats within the limit.

Install this device in your mushroom farm, and connect it with the exhaust system. Set the threshold, and voila!

Advantages of installing a CO2 monitoring device

- Supreme quality mushrooms

- High Yield

- Cost-effective

- Control in the growth process

- Less tedious

To read more of our marvels, click here.

To know more about what we do, click here.